Maintaining pH and CO2 Stability in Busy Cell Culture Incubators: A Guide for Consistent Results

For researchers, scientists, and drug development professionals, consistent cell culture results hinge on a stable incubator environment.

Maintaining pH and CO2 Stability in Busy Cell Culture Incubators: A Guide for Consistent Results

Abstract

For researchers, scientists, and drug development professionals, consistent cell culture results hinge on a stable incubator environment. This article provides a comprehensive guide to mastering pH and CO2 control in high-traffic shared incubators. It covers the foundational science of the CO2-bicarbonate buffer system, best practices for routine operation and maintenance, advanced troubleshooting for common problems, and essential strategies for GMP validation and performance comparison to ensure data integrity and reproducibility in critical research and clinical applications like IVF and biopharmaceutical production.

The Science of Stability: Why pH and CO2 are Non-Negotiable in Cell Culture

Core Principles and Frequently Asked Questions (FAQs)

What is the fundamental role of CO₂ in my cell culture medium?

CO₂ is not a direct metabolic requirement for most cultures; its primary purpose is to dissolve into the cell culture medium where a small proportion reacts with water to form carbonic acid. This acid then interacts with dissolved bicarbonate ions (from sodium bicarbonate, NaHCO₃, in the medium) to create a stable, physiological pH through the bicarbonate buffering system [1] [2]. This system mimics the natural buffering found in human and mammalian blood and tissues, minimizing toxic side effects for your cells [1].

Why does my medium's sodium bicarbonate concentration dictate the CO₂ setting on my incubator?

The amount of sodium bicarbonate in your medium formulation is precisely balanced with a specific concentration of CO₂ gas to maintain the correct pH. This relationship is governed by the Henderson-Hasselbalch equation [3]. If the CO₂ level in the incubator is too low for a given bicarbonate concentration, CO₂ will escape from the medium, causing it to become too alkaline. Conversely, if the CO₂ level is too high, the medium will absorb excess CO₂ and become too acidic [1] [4].

The table below summarizes the theoretical CO₂ requirements for different common media formulations to maintain a physiological pH range (7.2-7.4) at 37°C [1].

| Cell Culture Medium | Sodium Bicarbonate (NaHCO₃) Concentration | Required CO₂ Concentration for Physiological pH | Theoretical pH at 5% CO₂ |

|---|---|---|---|

| DMEM | 44 mM | 7.5% - 11% | ~7.5 (Slightly alkaline) |

| EMEM + Earle's Balanced Salt Solution | 26 mM | 4.5% - 6.5% (Nominal 5%) | Within physiological range |

| EMEM + Hank's Balanced Salt Solution | 4 mM | Near atmospheric levels | N/A |

Note for researchers: Although DMEM is theoretically formulated for 10% CO₂, it has become conventional to use it at 5%. Be aware that this can result in a slightly higher starting pH (7.5-7.6), which is often offset by the lactic acid and CO₂ produced by healthy, growing cultures [1].

Why is pH stability so critical for my cell cultures?

Cells are exquisitely sensitive to changes in proton (H⁺) concentration. Physiological pH is generally considered to be in the range of 7.2 to 7.4 for normal mammalian tissues [1]. Fluctuations outside this narrow range can severely impact [5] [4]:

- Enzyme activity and protein folding

- Cellular metabolism and growth rates

- Gene expression

- Overall cell viability, potentially triggering cell death

Besides CO₂/Bicarbonate, what other buffers can I use?

The CO₂/HCO₃⁻ buffer is the most physiologically relevant. However, synthetic non-volatile buffers (NVBs) like HEPES are often added to augment buffering capacity, especially during procedures outside the incubator where CO₂ can escape [1] [3].

- HEPES: pKa of 7.3 at 37°C, making it very effective in the physiological pH range [3].

- Function: These buffers work over a wider range of laboratory conditions and do not require a CO₂ atmosphere to function. They help maintain pH when the culture medium is exposed to room air [1].

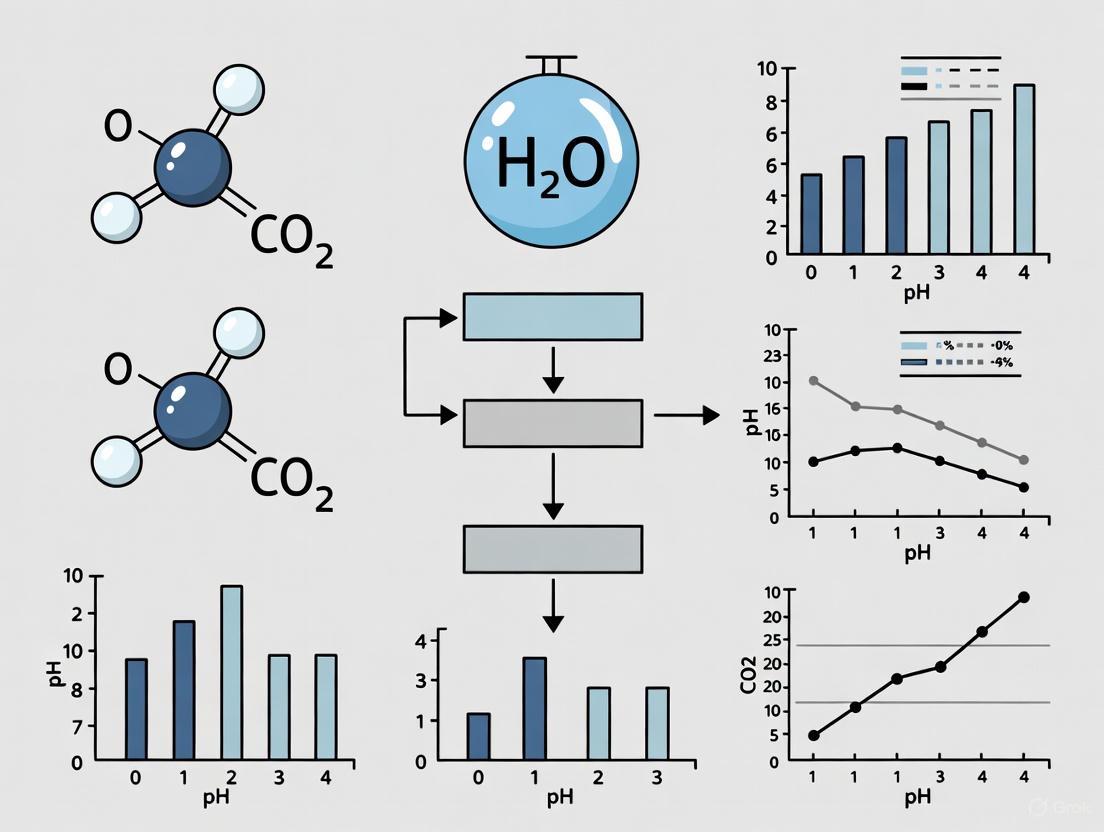

The following diagram illustrates the core chemical equilibrium of the CO₂-Bicarbonate buffer system and its interaction with a non-volatile buffer (like HEPES) in a cell culture environment.

Troubleshooting Common pH and CO₂ Stability Issues

Problem: The pH of my medium is consistently inaccurate or drifts unexpectedly.

| Possible Cause | Underlying Principle | Solution |

|---|---|---|

| Mismatch between CO₂ incubator setting and medium bicarbonate level. | The CO₂/HCO₃⁻ equilibrium is displaced, driving the pH away from the set point [1]. | Verify the sodium bicarbonate concentration of your medium and set the incubator to the corresponding CO₂ level (see table above). |

| Faulty or uncalibrated incubator sensor. | The displayed CO₂ percentage is inaccurate, leading to incorrect gas levels in the chamber [4]. | Regularly service and calibrate the incubator's internal CO₂ probe using an independent, calibrated CO₂ monitor [1] [4]. |

| Inadequate buffering capacity for the cell density or metabolic activity. | High cell densities produce metabolic acid (e.g., lactic acid) faster than the buffer can neutralize it [2]. | For high-density or fast-growing cultures, consider using a medium with higher bicarbonate, augmenting with HEPES buffer (10-25 mM), or increasing the media change frequency [3]. |

| Contamination with acids or bases. | Introduction of external substances can directly titrate the buffer, consuming its capacity [3]. | Ensure aseptic technique and avoid introducing any non-sterile solutions into the medium. |

Problem: My CO₂ incubator is struggling to stabilize its CO₂ levels.

| Possible Cause | Underlying Principle | Solution |

|---|---|---|

| Defective CO₂ sensor. | A malfunctioning sensor provides inaccurate readings, preventing proper feedback control [4]. | For Infrared (IR) sensors: Check calibration. For Thermal Conductivity (TC) sensors: Be aware these are highly sensitive to humidity and temperature fluctuations and may be less stable [4]. |

| Blocked or limited gas supply. | A partially opened valve, clogged regulator, or empty CO₂ tank restricts gas flow into the chamber [4]. | Inspect the gas supply system, including the cylinder, connections, and pressure hoses, for blockages or low pressure. Ensure the cylinder valve is fully open [4]. |

| Excessive door openings or inner door gasket leaks. | Frequent opening allows CO₂-rich air to escape, and a leaky gasket prevents the chamber from sealing properly [4]. | Minimize door opening frequency and duration. Organize contents to quickly find items. Inspect the door gasket for gaps or tears and replace if damaged [4]. |

Problem: My cell cultures are growing slowly or showing poor viability, and I suspect environmental stress.

| Possible Cause | Underlying Principle | Solution |

|---|---|---|

| Elevated CO₂ levels causing intracellular acidification. | Excess dissolved CO₂ can acidify the intracellular environment, disrupting enzyme function and suppressing glucose metabolism [2]. | Ensure your incubator is accurately calibrated. In large-scale bioreactors, active CO₂ removal may be necessary at high cell densities [2]. |

| Low humidity leading to medium evaporation and osmotic stress. | Evaporation concentrates salts and nutrients in the medium, creating a hyperosmotic environment that is toxic to cells [6] [4]. | Check and refill the incubator's water pan weekly with sterile distilled water. Ensure the pan is clean and positioned for good air circulation [6]. |

| Contamination from improper handling or incubator hygiene. | Microorganisms (bacteria, mold, mycoplasma) compete with cells for nutrients and release toxic byproducts [6]. | Follow aseptic technique: disinfect gloves with 70% ethanol, avoid reaching over open media, and do not stack culture vessels. Clean the incubator interior regularly and use HEPA filtration if available [6]. |

The Scientist's Toolkit: Essential Reagents and Materials

The following table details key reagents and materials essential for managing the CO₂-bicarbonate buffer system and maintaining pH stability in cell culture.

| Item | Function in pH Regulation & Culture Maintenance |

|---|---|

| Sodium Bicarbonate (NaHCO₃) | The conjugate base in the CO₂/Bicarbonate buffer system; neutralizes acids produced by cell metabolism to maintain physiological pH [1] [2]. |

| HEPES Buffer | A non-volatile buffer (NVB) added to media (typically 10-25 mM) to provide additional buffering capacity outside a controlled CO₂ environment, e.g., during sample manipulation on the bench [3]. |

| Phenol Red | A pH indicator dye added to most culture media. It provides a visual assessment of medium acidity: yellow (acidic, pH ~6.8), orange-red (optimal, pH ~7.4), and purple (alkaline, pH ~8.2) [1] [3]. |

| CO₂ Incubator | Maintains a precise, humidified atmosphere with a defined CO₂ concentration (typically 5-10%) and temperature (37°C) to sustain the chemical equilibrium of the bicarbonate buffering system [1] [5]. |

| Calibrated CO₂ Monitor | An independent, portable device used to verify and recalibrate the internal CO₂ probe of an incubator, ensuring accuracy of the displayed CO₂ percentage [1] [4]. |

| Cell Culture Grade Water | Used to fill the incubator's humidity pan. Must be sterile and distilled to prevent contamination and mineral deposits that can foster microbial growth [6]. |

Experimental Protocols for pH Management

Protocol 1: Quantifying Medium pH Using Phenol Red Absorbance

For a more precise measurement than visual inspection, you can quantify medium pH using the absorbance spectrum of Phenol Red [3].

- Prepare Calibration Standards: Create a series of bicarbonate-free medium standards with known pH, covering the expected range (e.g., pH 6.8 to 8.0). It is critical to use bicarbonate-free medium for calibration to prevent CO₂ loss from affecting the pH.

- Measure Absorbance: Using a plate reader with incubator chamber, scan the absorbance spectrum of each standard. Key wavelengths are 560 nm (base absorbance) and 430 nm (acid absorbance).

- Generate Standard Curve: For each standard, calculate the ratio of absorbance at 560 nm to that at 430 nm (A560/A430). Plot this ratio against the known pH to create a standard curve and obtain a best-fit equation.

- Measure Experimental Samples: Place your experimental culture medium (with cells removed) in the plate reader and measure the A560/A430 ratio.

- Calculate pH: Use the standard curve equation to convert the measured ratio of your sample into a precise pH value [3].

Protocol 2: Validating Incubator Environment via Temperature Mapping

To ensure your incubator provides a uniform and stable environment for all your cultures, perform periodic temperature mapping.

- Stabilization: Allow the CO₂ incubator to stabilize at the desired set point (e.g., 37°C) for several hours before beginning.

- Placement of Sensors: Position multiple calibrated, independent temperature sensors (or a multi-channel data logger) at various locations within the chamber, including the center, corners, and on different shelves.

- Data Collection: Record temperature data at regular intervals (e.g., every 15 minutes) over a period of 24 to 48 hours to capture any fluctuations over time. Monitor and log CO₂ levels simultaneously if possible.

- Data Analysis: Analyze the collected data to identify any significant variations, hot spots, or cold spots. Compare all recorded temperatures to the incubator's set point and your experimental tolerance range.

- Action: Investigate and resolve any deviations. This process is vital for compliance and to prevent experimental variability caused by an uneven culture environment [4].

The workflow for setting up and validating your cell culture system for optimal pH control is summarized in the following diagram.

Frequently Asked Questions (FAQs)

My cells are growing too slowly or have an unexplainable change in growth rate. What could be wrong? Check your incubation conditions first. Variations in temperature, CO₂ levels, or humidity due to frequent incubator door openings in a busy lab can stress cells and alter growth patterns. Also, ensure you are using the correct media formulation and that your cultures are not at an excessively high density, which can lead to nutrient depletion and altered growth physiology [7] [8] [9].

Why are my adherent cells not attaching properly to the culture vessel? This could be due to several factors. Verify that you are using culture dishes designed for adherent cells, as some have hydrophobic surfaces for suspension cultures. Your cell line may require a special coating like poly-L-lysine or collagen. Also, static electricity from handling plastic vessels in low-humidity environments can disrupt attachment [10] [7].

My experimental results, especially Western blot data for specific proteins, are inconsistent between replicates. Why? Fluctuations in cell population density are a major, often overlooked, source of variability. Protein markers for autophagy (p62, LC3II), lysosomal function (cathepsin D), and cellular signaling (mTOR, pS6) are highly sensitive to cell confluency due to changes in nutrient availability and cell crowding. Always standardize seeding density and confirm confluence at the time of harvesting [8].

How does the CO₂ concentration in my incubator actually affect my cells? CO₂ is not a direct metabolic requirement for most cell lines; its primary role is to dissolve in the culture medium and interact with bicarbonate to form a buffering system that maintains a stable physiological pH (typically 7.2-7.4). An incorrect CO₂ level will drive the medium's pH out of this optimal range, causing cellular stress and affecting health and reproducibility [1] [11].

I am struggling to reproduce my viral vector production yields. What should I check? Reproducible culturing is critical. For production cells like HEK 293, ensure your CO₂ incubator provides uniform conditions and recovers quickly after door openings. The quality attributes of viral particles can be greatly affected by subtle changes in temperature, CO₂, and humidity. Using a CO₂-resistant orbital shaker designed for incubation can also help maintain optimal growth conditions for suspension cultures [12].

Troubleshooting Guides

Guide to Troubleshooting Incubation Environment Fluctuations

A stable incubation environment is fundamental for reproducible cell culture. The table below outlines common problems, their consequences, and solutions.

| Problem | Consequence for Cells | Recommended Solution |

|---|---|---|

| Frequent incubator door openings | Fluctuations in temperature and CO₂; slower growth; altered physiology [7] [12] | Minimize door openings; place critical cultures at the back; use incubators with fast recovery times [12]. |

| Incorrect CO₂ level for media type | Non-physiological pH; cellular stress; changed metabolism [1] | Match CO₂ to bicarbonate concentration (e.g., 5% for ~26mM NaHCO₃, 10% for ~44mM NaHCO₃ in DMEM); calibrate incubator regularly [1] [11]. |

| Low humidity | Evaporation of culture medium; increased osmolarity; cell stress and desiccation [11] | Keep water reservoirs full; use incubators with humidification systems to maintain ~95% relative humidity [11] [7]. |

| Vibration | Unusual cell growth patterns (e.g., concentric rings) [7] | Place incubator on a sturdy surface away from motors, foot traffic, and other vibrating equipment [7]. |

Guide to Troubleshooting Cell Density and Culture Health

The density of your cell population directly impacts biochemistry and signaling, which can confound experimental outcomes.

| Problem | Consequence for Cells & Experiments | Recommended Solution |

|---|---|---|

| High Cell Density / Over-confluence | Nutrient depletion; acidification of media (yellow color); inactivation of mTOR signaling; altered expression of p62, LC3II, cathepsin D [8]. | Standardize seeding densities and harvesting schedules; always check confluence at time of experiment; refresh media more frequently in dense cultures [8]. |

| Mycoplasma Contamination | Chronic, subtle effects on cell health and metabolism; can alter data without causing cell death [10]. | Regularly test cultures; limit the routine use of antibiotics to avoid masking contamination; maintain strict aseptic technique [10]. |

| Poor Recovery from Frozen Stocks | Low cell viability; slow or no growth after thawing [10]. | Ensure proper freezing and thawing protocols; freeze a high number of cells per vial; seed thawed cells at a higher density to support recovery [10]. |

Quantitative Data: Impact of Cell Density on Protein Markers

Systematic research shows that fluctuating cell density alters key protein markers, leading to ambiguous experimental outcomes. The data below, derived from multiple cell lines, summarizes how high cell density biochemically confounds common readouts [8].

| Cellular Compartment | Protein Marker | Observed Change at High Density | Functional Consequence |

|---|---|---|---|

| Autophagy | p62 | ↓ Decreased [8] | Confounded interpretation of autophagy flux assays [8]. |

| LC3II | ↓ Decreased [8] | Altered autophagosome marker levels [8]. | |

| Lysosome | Cathepsin D (Mature) | ↑ Increased [8] | Enhanced lysosomal protease activity [8]. |

| Nutrient Signaling | pS6 (mTOR marker) | ↓ Decreased [8] | Indicative of mTOR pathway inactivation [8]. |

| Plasma Membrane | Na+/K+ ATPase | Variable (Scaling) | Altered ion transport and energy use [8]. |

| Nucleus | Lamin B1 | Variable (Scaling) | Changes in nuclear architecture [8]. |

Experimental Protocol: Analyzing Density-Dependent Protein Changes

- Cell Seeding: Plate cells (e.g., HEK 293FT, HeLa) at a range of densities (e.g., from 50,000 to 400,000 cells per well of a 6-well plate) in triplicate [8].

- Incubation: Culture cells for 48 hours in a standard humidified incubator at 37°C and 5% CO₂ [8].

- Media pH Check: Before harvesting, observe the color of the culture media using Phenol Red. A yellow hue indicates acidification, a sign of high metabolic activity and confluence. For a more precise measurement, use a pH meter [8] [1].

- Cell Lysis: After 48 hours, lyse cells directly in the culture dish using an appropriate lysis buffer (e.g., RIPA buffer supplemented with protease and phosphatase inhibitors) [8].

- Protein Quantification and Western Blot: Determine protein concentration using a standard assay (e.g., BCA). Load equal amounts of protein (e.g., 20 µg) onto an SDS-PAGE gel, transfer to a membrane, and probe with antibodies against your proteins of interest (e.g., p62, LC3B, pS6, cathepsin D). Use a stable loading control like GAPDH or actin [8].

Key Signaling Pathways Altered by Cell Density

The following diagram summarizes how high cell density impacts major signaling pathways, based on data from multiple cell lines [8].

High-Density Signaling Pathway Crosstalk

The Scientist's Toolkit: Essential Research Reagents and Materials

| Item | Function in Context of Stability | Example Application |

|---|---|---|

| Bicarbonate-Buffered Media | Works with CO₂ to maintain physiological pH in a humidified incubator [1]. | General cell culture maintenance. |

| HEPES-Buffered Media | Provides additional pH buffering capacity independent of CO₂, useful for workflows outside the incubator [1]. | During transfection or other extended room-temperature procedures. |

| Phenol Red | A pH indicator in media; yellow (acidic), purple (alkaline), orange-red (optimal) [1]. | Visual, rapid assessment of medium condition and cell metabolic state. |

| Trypsin / TrypLE | Proteolytic enzymes for dissociating adherent cells for subculturing [13]. | Passaging cells to maintain them in an optimal density range. |

| Cell Dissociation Buffer | Non-enzymatic, gentle solution for detaching sensitive cells while preserving surface proteins [13]. | When enzymatic activity could damage critical cell surface receptors. |

| Torin 1 | A potent and specific mTOR pathway inhibitor [8]. | Used experimentally to mimic the mTOR inactivation seen in high-density, nutrient-depleted conditions [8]. |

| Poly-L-Lysine | Coating agent that increases the adhesiveness of culture surfaces [10]. | Improving attachment for fastidious adherent cell lines. |

Troubleshooting Guides

Guide to Diagnosing and Correcting Microclimates in Shared Incubators

Problem: Uneven cell growth or inconsistent experimental results across different culture vessels within the same incubator.

Explanation: In a frequently accessed shared incubator, the internal environment is repeatedly disrupted. Without active measures to ensure uniformity, distinct microclimates—small areas with different temperature, CO2, or humidity levels—can form. This variability compromises experimental reproducibility [14].

Step 1: Verify the Existence of a Microclimate

- Method: Place multiple pre-calibrated sensors (for temperature, CO2, and relative humidity) at different locations inside the incubator: top shelf, bottom shelf, front, and back.

- Protocol: Close the door and allow the incubator to stabilize for several hours. Then, simulate shared use by opening the door briefly 5-10 times over an hour. Record the sensor readings before, during, and after these disturbances.

- Expected Outcome: Identify if and where environmental parameters deviate. For example, temperature may be higher on top shelves due to heat rising, and CO2 may stratify without active circulation [14].

Step 2: Identify the Root Cause

- Check Air Circulation: Incubators without a circulating fan or with a faulty fan are highly prone to stratification of gases and temperature [14].

- Monitor Door Opening Patterns: Correlate environmental data with lab usage logs to see if disturbances coincide with specific high-traffic periods.

- Inspect Seals and Sensors: Check the door seal for integrity and ensure environmental sensors are calibrated and functioning correctly [15].

Step 3: Implement Corrective Actions

- Optimize Incubator Layout: Reserve the most stable, central areas of the incubator for critical, long-term experiments. The back of the incubator is generally less affected by door openings [7].

- Improve User Practices: Establish and post lab guidelines for minimizing door open time and opening the door slowly and deliberately to reduce air exchange [16].

- Service Equipment: Schedule regular maintenance and calibration of sensors, fans, and humidity systems to ensure optimal performance [15].

Guide to Troubleshooting pH Instability in a Busy Lab

Problem: The pH of cell culture media shifts outside the optimal range (typically 7.2-7.5), indicated by frequent color changes in phenol red-containing media.

Explanation: The pH of culture media is maintained by a balance between the CO2 concentration in the incubator atmosphere and the bicarbonate buffer in the media. Frequent door openings allow CO2 to escape, causing the media to become more basic (pH rises). Conversely, if the CO2 sensor is faulty or calibration is off, the incubator may not deliver enough CO2, leading to the same issue [14] [17].

Step 1: Confirm the pH Shift

- Method: Visually inspect the color of media in several culture vessels. Use a pH meter for precise measurement.

- Protocol: Compare the color/media pH of cultures located near the door with those at the back of the incubator after a period of high usage.

Step 2: Isolate the Cause

- Test CO2 Recovery: Use a portable CO2 meter to measure the gas concentration immediately after a door closing. Time how long it takes for the level to return to 5%. A slow recovery indicates a potential issue with the CO2 sensor, solenoid valve, or gas mixing [14].

- Check for Proper Humidification: Low humidity increases media evaporation, concentrating salts and buffers and altering pH. Ensure water reservoirs are filled with sterile, distilled water (pH 7-9) and are clean to prevent corrosion and microbial growth [16] [18].

- Inspect Gas Filters: Ensure the 0.3-micron inlet filter on the CO2 gas supply line is clean and not clogged, as this can restrict gas flow [19].

Step 3: Implement Corrective Actions

- Calibrate CO2 Sensor: Follow the manufacturer's protocol to calibrate the CO2 sensor. This should be part of a routine maintenance schedule.

- Use Active Airflow: Ensure the incubator's fan is operational to prevent CO2 stratification and ensure a homogeneous gas mixture [14].

- Seal Culture Vessels: Use parafilm or gas-permeable seals on multi-well plates and flasks to minimize media evaporation and gas exchange during storage [16].

Frequently Asked Questions (FAQs)

Q1: What are the most common causes of condensation forming on the inside of my culture vessel lids, and how can I prevent it? A: Condensation occurs when warm, humidified air from the incubator contacts a cooler surface, like a culture vessel lid. This is often caused by:

- Cold Spots: Temperature inconsistencies within the incubator chamber, often due to lack of uniform heating [16].

- Rapid External Changes: Placing a room-temperature culture vessel directly into the warm incubator.

- Prevention: Choose an incubator with features like outer-door heaters that warm the glass door to ambient temperature, or dew sticks/Peltier elements that direct and control condensation. Also, allow culture vessels to warm gradually near the incubator before placing them inside to minimize the temperature differential [16].

Q2: Our lab's incubator is constantly in use. What is the single most effective practice to protect my cells from these disturbances? A: The most effective practice is to minimize the frequency and duration of door openings. This can be achieved by:

- Planning ahead to retrieve or place all necessary items in a single, swift access.

- Opening the door slowly and only as much as necessary, as a fast opening creates more turbulent airflow and a sharper drop in humidity [16].

- Advocating for lab-wide scheduling or designated incubator spaces to reduce peak traffic.

Q3: How does incubator design impact its ability to handle the challenges of a shared environment? A: Key design features significantly improve stability in shared settings:

- Active Airflow/Circulating Fan: Crucial for maintaining uniform temperature and CO2 levels throughout the chamber, preventing stratification [14].

- Rapid Recovery Systems: Incubators with advanced sensors and efficient heating/humidification systems can quickly restore set parameters after a door is closed.

- HEPA Filtration: Continuously filters the internal air, reducing the risk of contamination introduced during door openings [14].

- Air-Jacketed Technology: Provides faster temperature recovery after door openings compared to water-jacketed models [16].

Q4: Beyond the incubator itself, what lab practices can reduce contamination risks in a shared incubator? A: Strict aseptic technique is paramount. Key practices include:

- Regular Decontamination: Wiping down the interior and shelves with a 70% ethanol solution before and after use [19].

- External Cleanliness: Ensuring all culture vessels, shakers, and other equipment placed inside the incubator are decontaminated on the outside first [19].

- Proper Location: Installing the incubator in a low-traffic area away from HVAC vents, which can introduce airborne contaminants [19].

Table 1: Impact of Shared Incubator Disturbances on Key Parameters

| Parameter | Ideal Range | Impact of Frequent Access | Consequence for Cell Cultures |

|---|---|---|---|

| Temperature | 37°C [17] | Fluctuations with each door opening; heat rises causing top shelves to be warmer [7] [14] | Decreased metabolic function, inhibited growth, cell death; altered gene expression [14] |

| CO₂ Concentration | ~5% [17] | Gas escapes; without airflow, CO₂ stratifies (higher at bottom) [14] | Disrupted pH (becomes basic); altered cell morphology, metabolism, and stress [14] |

| Relative Humidity | 85-95% [16] [17] | Drops as dry room air enters; media evaporates faster at the edges of plates [16] [7] | Increased concentration of media components ("edge effect"); changes in cell proliferation/gene expression [16] |

| Contamination Risk | N/A | Introduction of airborne microbes and spores with each door opening [19] | Microbial growth; changes in cell behavior, morphology, and potential cell death [16] |

Table 2: Quantitative Market and Performance Data for CO₂ Incubators

| Data Category | Specific Figure | Context and Significance |

|---|---|---|

| Global Market Size (2024) | USD 506 Million [20] | Indicates the widespread use and economic importance of CO2 incubators in life sciences. |

| Projected Market Size (2032) | USD 818 Million [20] | Reflects anticipated growth and continued reliance on this technology, driven by biotech and pharmaceutical sectors. |

| Forecast CAGR (2025-2032) | 7.3% [20] | Highlights a robust and steadily growing market. |

| Top 3 Player Market Share | 55% (Thermo Scientific, Eppendorf, PHC) [20] | Market is highly concentrated, with a few established leaders driving innovation and standards. |

| HEPA Filtration Target | Achieve ISO Class 5 air quality [14] | A key performance metric for advanced contamination control features. |

Experimental Protocols

Protocol: Assessing Microclimate Variability and Door-Opening Impact

Objective: To quantitatively measure the spatial and temporal variability of temperature, CO2, and humidity within a shared cell culture incubator under typical use conditions.

Background: The reliability of cell culture experiments depends on a homogeneous incubator environment. This protocol provides a methodology to validate incubator performance and identify zones of instability [7] [14].

Materials:

- Shared CO2 incubator

- 4-6 pre-calibrated, data-logging sensors for temperature, CO2, and relative humidity

- Timer

- Lab notebook

Methodology:

- Sensor Placement: Position the sensors at strategic locations within the empty incubator: top-left shelf, top-right shelf, bottom-center shelf, and near the door.

- Baseline Measurement: Close the incubator door and allow the system to stabilize for at least 12 hours (e.g., overnight). Record the baseline measurements from all sensors once they are stable.

- Simulated Usage Phase: Over the next 8 hours, simulate a typical busy lab day. Have lab members open the incubator door 10-15 times at random intervals. For each opening, the door should be held open for approximately 15-20 seconds.

- Data Collection: Ensure all data loggers are recording measurements throughout the entire stabilization and test period.

- Recovery Test: After the final door opening, note the time and record how long it takes for each parameter at each sensor location to return to within 1% of the baseline value.

Expected Outcomes:

- Identification of "hot spots" or "cold spots" for temperature.

- Data on CO2 stratification and recovery time post-disturbance.

- Mapping of humidity gradients, particularly near the door.

- This data can be used to create an "optimal placement map" for sensitive cultures within the specific incubator.

Protocol: Validating a Mini-Incubator for Long-term Live-Cell Imaging

Objective: To confirm that a portable on-stage mini-incubator can maintain environmental stability comparable to a standard tissue culture incubator, specifically for long-term imaging applications where frequent access is not a factor.

Background: Standard incubators are incompatible with prolonged microscopy. Mini-incubators allow for continuous imaging but must be validated to ensure they do not introduce environmental stress. This protocol is adapted from methods used in peer-reviewed literature [17].

Materials:

- Standard CO2 incubator (control)

- Portable on-stage mini-incubator (test device)

- VERO or MDA-MB-231 cell lines

- DMEM/High glucose culture medium supplemented with 15% FBS and 1% penicillin/streptomycin

- 24-well plates

- Crystal violet staining solution, MTT reagent, and flow cytometry reagents for apoptosis

Methodology:

- Cell Seeding: Seed cells in multiple 24-well plates at a standardized density.

- Incubation: Place one set of plates in the standard incubator and another set in the mini-incubator, both set to 37°C, 5% CO2, and >90% humidity.

- Viability and Adhesion Assay (Crystal Violet): After 24 and 48 hours, fix cells with glutaraldehyde or ethanol and stain with crystal violet. Compare the stained cell adhesion patterns and density between the two environments [17].

- Metabolic Activity Assay (MTT): At 48 hours, add MTT reagent to wells to assess cell metabolic activity. Measure the absorbance of the formed formazan product; comparable values indicate healthy cells in both incubators [17].

- Apoptosis Assay (Flow Cytometry): After 72 hours, harvest cells and stain with Annexin V and PI to detect early and late apoptosis/necrosis. The percentage of apoptotic cells should be similar between the standard and mini-incubator [17].

Expected Outcomes:

- Validation that the mini-incubator supports cell adhesion, viability, and normal apoptosis rates equivalent to a standard incubator.

- Confirmation that the device is suitable for long-term, stable live-cell imaging experiments without compromising cell health.

Diagrams and Workflows

Cause and Effect of Shared Incubator Use

Troubleshooting and Mitigation Workflow

The Scientist's Toolkit: Key Reagent and Material Solutions

Table 3: Essential Materials for Maintaining Incubator Integrity and Cell Health

| Item | Function | Key Consideration for Shared Environments |

|---|---|---|

| Pre-calibrated Data Loggers | To continuously monitor temperature, CO2, and humidity levels inside the incubator to identify microclimates and recovery times. | Essential for objective validation of incubator performance and troubleshooting variability [7]. |

| Sterile, Distilled Water (pH 7-9) | For filling the incubator's humidity pan to maintain >90% relative humidity. | Prevents corrosion of stainless-steel components and avoids introducing impurities or altering pH [16]. |

| 70% Ethanol Solution | For decontaminating the interior surfaces, shelves, and door seal of the incubator. | Proper dilution allows sufficient contact time to kill microbes before evaporation. Regular use is critical in shared spaces [19]. |

| CO2 Inlet Filter (0.3 micron) | Placed in the gas supply line before the incubator to sterilize the incoming CO2 gas. | Prevents the introduction of microbial contaminants through the gas stream, a often-overlooked vector [19]. |

| Gas-Permeable Seals | Used to seal multi-well plates and flasks, such as during extended non-observation periods. | Significantly reduces media evaporation (preventing the "edge effect") and minimizes gas exchange fluctuations during door openings [16]. |

FAQs: Maintaining Incubator Stability in a Busy Lab

Q1: Our lab's CO2 incubator struggles to maintain a stable pH in our culture media. What are the most likely causes?

The stability of pH is directly controlled by the CO2-bicarbonate buffering system in your culture medium. Instability often stems from issues with the CO2 sensor, incubator door openings, or a mismatch between your culture medium and the set CO2 percentage [21] [1].

- CO2 Sensor Performance: A malfunctioning or uncalibrated CO2 sensor cannot accurately regulate the gas concentration. Infrared (IR) sensors are less affected by temperature and humidity fluctuations, while Thermal Conductivity (TC) sensors can provide inaccurate readings if humidity changes, such as after a door opening [21].

- Frequent Door Openings: Each time the incubator door is opened, humidified air is replaced with drier room air, causing fluctuations in CO2, temperature, and humidity. A 30-second door opening can require over 30 minutes for the environment to fully restabilize [21] [16].

- Medium/CO2 Mismatch: The required CO2 concentration depends on the sodium bicarbonate level in your medium. For example, DMEM (with 44mM NaHCO3) theoretically requires 7.5-11% CO2 to maintain a physiological pH of 7.2-7.4, but is often used at 5%, which can result in a slightly alkaline pH (7.5-7.6) [1].

Q2: We observe excessive condensation and media evaporation in our incubators. How does the humidification system contribute to this?

These issues are two sides of the same coin, related to poor humidification control [16].

- Media Evaporation: This occurs when humidity is too low (below 85-95%). Water evaporates from the culture media, leading to increased concentration of salts and nutrients, which disrupts cell growth and causes an "edge effect" in multiwell plates [16].

- Condensation: This happens when humidity is too high, often due to temperature instability. If the temperature drops slightly, the air can no longer hold as much moisture, leading to condensation on surfaces and vessel lids. This moisture promotes microbial growth and contamination [21] [16].

- Key Causes: Common causes include low water levels in the humidity pan, use of incorrect water type (which can cause corrosion), and frequent door openings that allow dry room air to enter [21] [16] [22].

Q3: What routine maintenance is critical for the sensors and humidification system?

A proactive maintenance schedule is essential for consistent performance [22] [23].

- CO2 Sensor Calibration: Sensors should be checked and calibrated by a professional technician approximately every six months. You can verify readings with an independent, calibrated CO2 meter [21] [23].

- Humidification System Upkeep: The water pan should be refilled with sterile, distilled water (pH 7-9) to prevent corrosion. The water should be changed completely every 1-2 weeks to limit microbial growth [16] [22].

- General Cleaning & Filter Replacement: The incubator chamber and humidity pan should be cleaned and disinfected regularly (e.g., with 70% ethanol). The HEPA filter, which cleans the circulating air, should be replaced yearly [22] [23].

Troubleshooting Guides

Problem: Unstable CO2 Concentration and pH Drift

| Possible Cause | Diagnostic Steps | Solutions & Preventive Measures |

|---|---|---|

| Faulty or Uncalibrated CO2 Sensor [21] | Use a certified external CO2 gas analyzer to compare readings with the incubator display [21] [1]. | Schedule professional sensor calibration every 6 months [23]. |

| Frequent/Door Openings [21] | Monitor lab practices; note if instability correlates with high traffic. | Implement organized shelf management to reduce search time. Open the door slowly and only when necessary [21] [16]. |

| Blocked Gas Supply [21] | Check that the CO₂ cylinder valve is fully open. Inspect the regulator for ice (freeze-up) or debris [21]. | Ensure gas supply pressure is adequate. Replace empty or faulty gas cylinders [21]. |

| Incorrect CO2 for Culture Medium [1] | Check the sodium bicarbonate concentration of your medium and calculate the theoretical required CO2%. | Adjust the incubator's CO2 set point to match the medium's requirement (typically 5% for 26mM NaHCO3, 10% for 44mM NaHCO3) [1]. |

Problem: Inconsistent Humidity (Evaporation or Condensation)

| Possible Cause | Diagnostic Steps | Solutions & Preventive Measures |

|---|---|---|

| Low Water Level or Stagnant Water [16] | Check the water level in the humidity pan. Note the last time the water was changed. | Refill the pan with sterile distilled water. Change water weekly and clean the pan to prevent biofilm [22]. |

| Frequent Door Openings [16] | Observe recovery time after door openings. | Raise the lowest shelf to improve air circulation around the water pan. Keep the door closed as much as possible [21] [16]. |

| Unstable Temperature [16] | Verify the incubator's temperature stability and check for hot/cold spots via mapping. | Ensure the incubator is not near HVAC vents or heat sources. Perform temperature mapping to identify unevenness [21] [16]. |

| Faulty Door Gasket [21] | Inspect the inner door gasket for gaps, deformation, or tears. | Seal small gaps with silicon sealant. Replace the gasket if damaged [21]. |

Quantitative Data for Incubator Management

| Cell Culture Medium | Sodium Bicarbonate (NaHCO3) | Theoretical pH at 5% CO2 | Theoretical pH at 10% CO2 |

|---|---|---|---|

| EMEM + Hank's BSS | 4 mM | ~7.8 | ~7.4 |

| EMEM + Earle's BSS | 26 mM | ~7.4 | ~7.0 |

| DMEM | 44 mM | ~7.6 | ~7.2 |

| Sensor Type | Technology Principle | Pros/Cons | Impact on Control |

|---|---|---|---|

| Infrared (IR) | Measures absorption of infrared light by CO2 molecules. | High accuracy, stable, not affected by humidity/temperature changes. | Provides reliable, consistent CO2 control for stable pH. |

| Thermal Conductivity (TC) | Measures resistance to electrical flow compared to ambient air. | Sensitive to humidity and temperature; less accurate after door openings. | Can lead to pH instability as readings drift with environmental changes. |

Experimental Protocols

Purpose: To identify hot or cold spots within the incubator chamber and ensure uniform temperature distribution.

Methodology:

- Stabilization: Allow the incubator to stabilize at the desired set point (e.g., 37°C) for several hours before starting.

- Sensor Placement: Place multiple calibrated temperature sensors (data loggers) at various locations within the chamber, including the center, corners, and near the door and vents. Place them on different shelves.

- Data Collection: Securely close the door and start recording temperature data from all sensors simultaneously at regular intervals (e.g., every 15 minutes).

- Duration: Continue data collection for a minimum of 24 to 48 hours to capture fluctuations over time.

- Data Analysis: Analyze the collected data to identify any significant variations or patterns. Compare all readings to the incubator's set point and specified tolerance range. Investigate any persistent hot or cold spots.

Purpose: To independently verify the accuracy of the incubator's internal CO2 sensor and display.

Methodology:

- Equipment: Obtain a portable CO2 gas analyzer that has been recently calibrated to a recognized standard (e.g., UKAS).

- Stabilization: Ensure the incubator has been running stably at its set point for several hours with minimal door openings.

- Measurement: Carefully place the probe of the external analyzer inside the incubator chamber, close to the internal sensor, and close the door.

- Comparison: Allow the external analyzer reading to stabilize. Compare this reading to the CO2 concentration displayed on the incubator.

- Action: If a significant discrepancy is found (e.g., >0.2%), the incubator's internal sensor likely requires professional calibration.

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function | Application Note |

|---|---|---|

| HEPES Buffer | A synthetic pH buffer that operates effectively outside of CO2 environments. | Used to stabilize pH during procedures outside the incubator or in incubators without CO2 control [1]. |

| Phenol Red | A pH indicator dye added to most culture media. | Provides visual pH assessment: yellow (acidic), purple (alkaline), orange-red (physiological) [1]. |

| Cell Dissociation Buffer (Non-enzymatic) | A buffer that chelates calcium and magnesium to disrupt cell-cell and cell-substrate adhesion. | Ideal for gentle dissociation of sensitive cells when intact surface proteins are required for downstream assays [13]. |

| TrypLE Express Enzyme | A recombinant enzyme that functions as a direct substitute for trypsin. | Animal-origin free, stable at room temperature, and does not require inhibition post-dissociation, simplifying the subculture process [13]. |

| Sterile Distilled Water | High-purity water with a neutral pH used for humidification. | Premedia corrosion of stainless-steel incubator components. Using deionized water is not recommended [16]. |

Troubleshooting Logic Workflow

The following diagram outlines a systematic approach to diagnosing and resolving common incubator issues related to pH and humidity stability.

Proactive Protocols: Daily Practices for Sustaining Optimal Incubator Conditions

A guide to preserving pH and CO₂ stability for reproducible results

Why It Matters: The Impact of Door Openings on Incubator Stability

Every time a CO₂ incubator door is opened, the stable internal environment is compromised, leading to rapid fluctuations in temperature, humidity, and gas concentration. These disruptions can significantly impact cell health and experimental reproducibility by causing shifts in media pH and osmolality.

Table 1: Recovery Times After a 30-Second Door Opening [24]

| Parameter | Magnitude of Disruption | Typical Recovery Time |

|---|---|---|

| Temperature | Significant drop | > 30 minutes [24] |

| CO₂ Level | Drop in concentration | 2 - 10 minutes [25] |

| Relative Humidity | Sharp decrease | Varies by technology [26] |

Core Strategies for Minimizing Door Openings

Lab Management and Workflow Policies

- Assign Shelf Territories: Dedicate specific shelves to individual researchers or distinct cell lines. This eliminates unnecessary searching and reduces door-open time [24] [16].

- Create an Inventory System: Maintain a logbook or digital map outside the incubator detailing the location of every experiment. Know exactly what you need and where it is before opening the door [24].

- Batch Retrieval and Seeding: Plan work to consolidate incubator access. Retrieve all required materials for a given task (e.g., feeding, passaging) at once, rather than in multiple trips [16].

- Schedule Access: In busy shared labs, establish designated time slots for different users or groups to prevent queueing and frequent interruptions.

Optimizing User Behavior and Technique

- "Slow is Smooth, Smooth is Fast": Open the incubator door slowly and deliberately. A rapid opening creates greater airflow disruption, forcing more humid air out and pulling drier room air in, which extends recovery time [16].

- Minimize "Head-in-Incubator" Time: Prepare all tools (pipettes, reagents, waste containers) at your bench before approaching the incubator. Perform all actions inside the chamber with purpose and efficiency.

- Use the Viewing Window: Before opening the door, use the inner glass door and viewing window to visually locate your samples. Modern incubators are designed for this purpose to reduce unnecessary exploration [24].

Leveraging Incubator Technology and Features

- Choose an Incubator with a Fast Recovery System: When purchasing a new incubator, evaluate its recovery performance. Models with active humidification systems and powerful, directed heating elements can restore stable conditions more rapidly after a disturbance [16] [26].

- Utilize Inner Glass Doors: Always keep the inner glass door closed while the outer door is open. This provides a buffer, mitigating the exchange of the internal atmosphere with the room air [24].

- Consider a Unit with a Door Lock: For extremely sensitive, long-term experiments, use the incubator's door lock feature (if available) to prevent accidental interruptions by other users [24].

Experimental Protocol: Mapping Your Incubator's Recovery Profile

This protocol helps you quantify how door openings affect your incubator's environment, providing data to optimize your lab's workflows.

Table 2: Key Reagent Solutions for Incubator Maintenance [16] [26]

| Material | Function | Key Specification |

|---|---|---|

| Sterile, Distilled Water | For humidity pans; prevents corrosion and biofilm. | pH between 7.0 and 9.0 [16] [26] |

| 70% Ethanol Solution | For routine decontamination of interior surfaces and door gaskets. | N/A |

| Mycobactericidal Agent (e.g., MycGuard-1) | Added to water trays to eliminate mycobacteria and reduce contamination risk from condensation [27]. | N/A |

| Calibrated Hygrometer | Independent verification of the incubator's relative humidity display. | N/A |

| NIST-Traceable Thermometer | Independent verification of temperature uniformity and sensor accuracy [24]. | N/A |

Methodology

- Stabilization: Ensure the incubator has been operating undisturbed at your standard setpoints (e.g., 37°C, 5% CO₂, 95% RH) for at least 24 hours.

- Sensor Placement: Position pre-calibrated, NIST-traceable data loggers inside the chamber to record temperature, CO₂, and relative humidity at a high frequency (e.g., every 30 seconds). Place them in the geometric center and at potential vulnerable spots (e.g., near the door).

- Simulate Door Opening: Perform a standardized door opening representative of a sample retrieval (e.g., full open for 30 seconds).

- Data Collection: Allow the incubator to recover, logging data until all parameters have returned to their pre-defined setpoint ranges.

- Analysis: Plot the data to visualize recovery curves and calculate precise recovery times for each parameter. Repeat under different conditions (e.g., 15-second opening, open inner door) to build a comprehensive profile.

Troubleshooting FAQs

Q1: Our CO₂ levels are not stabilizing despite minimizing door openings. What else could be wrong? A1: If door management doesn't resolve CO₂ instability, investigate these technical issues [24] [25]:

- Check the CO₂ Sensor: Thermal Conductivity (TC) sensors are highly sensitive to humidity fluctuations caused by door openings and can drift. Infrared (IR) sensors are more stable and unaffected by humidity. Check your sensor type and calibration status.

- Inspect for Leaks: Examine the door gasket for deformations, tears, or gaps. Worn gaskets can leak CO₂, forcing the system to work constantly. Gaps can be sealed with a silicon sealant, but damaged gaskets should be replaced.

- Verify Gas Supply: Ensure the CO₂ cylinder valve is fully open and the regulator is not faulty, clogged, or frozen.

Q2: How can we actively prevent condensation caused by humidity and temperature fluctuations from door openings? A2: Condensation is a direct result of warm, humid air contacting a cooler surface [27] [16]. Mitigation strategies include:

- Control Temperature Gradients: Use incubators with features like heated glass doors to keep surfaces warm and prevent cooling.

- Optimize Air Circulation: Ensure the internal fan is functioning to promote even temperature distribution and eliminate cold spots.

- Use Anti-Condensation Products: Consider using a mycobactericidal agent in your water tray to reduce contamination risks from any condensation that does form [27].

Q3: What is the single most effective practice to reduce evaporation from our culture media? A3: The most effective practice is the combination of maintaining humidity above 93% and minimizing door openings [26]. Evaporation is four times faster at 80% humidity compared to >93%. Each door opening drops the humidity drastically, so keeping the door closed allows the incubator to maintain a protective, high-humidity environment.

Logical Workflow for Minimizing Incubator Disturbances

The following diagram outlines the strategic workflow for protecting your cell cultures by minimizing door openings, integrating both human practices and technical solutions.

Frequently Asked Questions (FAQs)

Q1: Why is organizing cultures for optimal airflow inside a CO₂ incubator so important? Proper airflow organization is critical for maintaining uniform temperature, CO₂, and humidity levels throughout the incubator chamber. In a busy lab, frequent door openings can cause fluctuations. Strategic organization minimizes these disturbances, ensuring experimental reproducibility and providing a stable environment for sensitive cells like stem cells and primary cultures [28].

Q2: How can improper organization affect my cell cultures? Poor organization can lead to the formation of "hot spots" or "cold spots"—areas with inconsistent temperature or CO₂ levels [29]. This can stress cells, compromise their health, and lead to inconsistent experimental results [11] [28]. It can also increase the risk of cross-contamination between different culture vessels [28].

Q3: What are the best practices for arranging culture vessels inside the chamber? The key principle is to arrange flasks and plates symmetrically on the shelves [30]. Avoid overloading the chamber and ensure vessels are not blocking the internal airflow pathways or sensors. This promotes balanced air circulation and helps the incubator recover more quickly after the door is closed [28].

Q4: What specific incubator features support better airflow management? Look for incubators with features like active airflow technology (e.g., fans) for consistent distribution of temperature and gases, validated temperature uniformity mapping, and HEPA filtration systems to remove airborne contaminants while circulating air [11] [28]. Some models also offer segregated chambers (e.g., cell locker systems) to physically separate different users or cell lines [28].

Troubleshooting Guides

Problem 1: Inconsistent Cell Growth Across Different Areas of the Incubator

Symptoms: Cells in cultures located on different shelves grow at different rates or show varying viability.

| Possible Cause | Troubleshooting Steps | Preventive Measures |

|---|---|---|

| Temperature Gradients | 1. Use a calibrated, independent thermometer to verify temperature at different shelves and locations [30].2. Check for overloading, which can restrict air circulation [30]. | Request a temperature uniformity map (e.g., DIN 12880 compliant) from the manufacturer before purchase [28]. |

| Uneven CO₂ Distribution | 1. Check and calibrate the CO₂ sensor per the manufacturer's schedule [30].2. Verify that culture vessels are not obstructing gas inlets or sensors. | Choose an incubator with a well-designed gas distribution system and high-quality sensors [11]. |

| Poor Airflow Organization | 1. Rearrange cultures to ensure symmetrical loading and avoid blocking air vents [30].2. Use computational fluid dynamics (CFD) or thermal imaging to identify airflow problems [29]. | Implement a lab-wide organization scheme (e.g., by project or user) and use incubators with active airflow technology [28]. |

Problem 2: Slow Recovery of CO₂ and Temperature After Door Opening

Symptoms: The incubator takes a long time to return to the set parameters after being accessed, which is a common issue in shared, busy labs.

| Possible Cause | Troubleshooting Steps | Preventive Measures |

|---|---|---|

| Frequent/Door Openings | 1. Review lab workflows to minimize door open time.2. Use the incubator's viewing window to locate items before opening. | Implement a culture segregation system (e.g., cell lockers) to reduce how often the main chamber is accessed [28]. |

| Overloaded Chamber | 1. Reduce the number of vessels in the chamber to improve air circulation.2. Ensure vessels are arranged to allow air to flow around them [30]. | Consider acquiring a second incubator to distribute the workload. |

| Incubator Type/Capacity | 1. Check if the incubator's recovery performance is suited for the lab's usage intensity.2. Verify that the door seal is intact and not compromised [30]. | Select direct-heat incubators for faster temperature recovery times [11]. |

Experimental Protocol: Verifying Chamber Uniformity

Objective: To empirically determine the temperature and CO₂ uniformity across different zones of a CO₂ incubator.

Background: Manufacturer specifications provide theoretical performance. This protocol allows researchers to verify that their specific organization scheme maintains a uniform environment for their precious cultures [28].

Materials Needed:

- CO₂ incubator

- 3-6 independent, calibrated data loggers capable of logging temperature and (if possible) CO₂.

- Timer

Methodology:

- Placement of Loggers: Position the data loggers in various locations inside the empty chamber. Key locations include:

- Top, middle, and bottom shelves.

- Front, center, and back of a single shelf.

- Near the CO₂ sensor and in a far corner.

- Stabilization: Close the incubator door and allow the chamber to stabilize at the set point (e.g., 37°C, 5% CO₂) for a minimum of 4-6 hours.

- Initial Reading: Record the temperature and CO₂ values from all loggers and the incubator's display.

- Door Opening Simulation: Open the incubator door fully for 30 seconds to simulate a typical access event, then close it.

- Recovery Monitoring: Immediately start the timer and record the readings from all loggers every minute until all values have returned to the stable baseline recorded in Step 3. Note the time it takes for each zone to recover.

- Data Analysis: Calculate the variance between different zones during stability and the average recovery time.

Interpretation: This experiment will reveal any significant gradients in your incubator and show how your organization might affect cultures in different locations. Zones with consistently slower recovery or different stable values should be considered less ideal for sensitive cultures.

Research Reagent Solutions

The following table lists key reagents and materials essential for maintaining cell health during the dissociation process that occurs before cultures are placed in the incubator.

| Item | Function & Application |

|---|---|

| Trypsin-EDTA | An enzymatic solution used to dissociate adherent cells from the culture vessel surface for subculturing. It is a standard for strongly adherent cells [13]. |

| TrypLE Express | A non-animal origin, ready-to-use enzyme that serves as a direct substitute for trypsin. It minimizes damage to cell surface proteins and is gentler on sensitive cells [13]. |

| Cell Dissociation Buffer | A non-enzymatic, gentle solution used to dissociate lightly adherent cells. It is ideal for applications where you need to keep cell surface receptors and antigens intact [13]. |

| Dispase | An enzyme used to detach cells as intact sheets, which is particularly useful for epidermal cells or organoid cultures. It works well in combination with collagenase for tissue dissociation [13]. |

| Collagenase | An enzyme used for the disaggregation of primary tissues, especially those with strong connective tissue, like those high in collagen [13]. |

| HEPES-Buffered Medium | Provides additional buffering capacity to maintain pH stability outside the CO₂ incubator environment, such as during cell manipulation at the bench [28]. |

Diagrams

Diagram 1: Stable vs. Disrupted Incubator Environment

Stable vs. Disrupted Incubator Environment

Diagram 2: Relationship Between Organization and pH Stability

Organization's Impact on pH Stability

This guide provides a foundational maintenance schedule. Always consult your incubator's specific user manual for detailed instructions and approved protocols.

Troubleshooting Guides

Incubator Performance Issues and Solutions

| Symptom | Possible Causes | Troubleshooting Steps | Prevention & Notes |

|---|---|---|---|

| CO₂ concentration will not stabilize or is inaccurate [31] | - Faulty CO₂ sensor- Gas supply issue- Controller defect- Door opened frequently [31] | - Check for error messages and power cycle [32]- Calibrate the TC CO₂ sensor [33]- Verify gas supply lines are connected and not empty- Use an independent, calibrated CO₂ monitor to verify readings [1] | - Choose incubators with IR CO₂ sensors for faster recovery after door openings [31]- Minimize door opening time and frequency |

| pH drift in culture media (Media color changes) [1] | - Incorrect CO₂ level for medium bicarbonate [1]- Faulty incubator CO₂ control- Evaporation of media due to low humidity | - Verify CO₂ level matches medium formulation (e.g., 5% for 26mM NaHCO₃, ~10% for 44mM NaHCO₃) [1]- Check incubator humidity pan for water [34]- Calibrate CO₂ sensor and inspect door seals [33] [32] | - Pre-equilibrate media in the incubator before use- Use HEPES-buffered media for extra pH stability outside the incubator [3] |

| Temperature fluctuations [32] | - Faulty temperature sensor- Compromised door seal- Overloaded chamber blocking airflow | - Verify temperature settings and allow time to stabilize [32]- Check door gasket for damage or creases [34]- Rearrange cultures to ensure proper air circulation- Schedule sensor calibration [32] | - Perform regular calibration checks- Avoid blocking internal fans and sensors with flasks |

| Visible contamination or microbial growth [35] [32] | - Infrequent cleaning- Unaddressed spills- Improper decontamination | - Immediate cleaning: Use 70% ethanol to wipe all surfaces [34]- Perform a full heat or H₂O₂ vapor decontamination cycle [35] | - Schedule regular preventive cleaning and decontamination [32]- Always use proper aseptic technique when handling cultures |

Decontamination Method Comparison

| Method | Typical Log Reduction | Advantages | Disadvantages | Best For |

|---|---|---|---|---|

| Dry Heat Sterilization [35] | Log 6 (Bacteria & spores) | - No toxic residues- Avoids moisture-related damage (rust/corrosion) | - High temps can damage heat-sensitive parts- Energy-intensive | - Labs requiring the most robust, globally recognized sterilization [35] |

| Moist Heat Decontamination [35] | Log 6 (Bacteria) Log 4 (Spores) | - Steam penetrates crevices- No toxic residues- Lower temperatures than dry heat | - Residual moisture requires drying, increasing downtime- Requires a water source | - Routine decontamination; effective against common fungi and bacteria [35] |

| Hydrogen Peroxide Vapor (HPV) [35] [34] | Log 6 (Bacteria & spores) | - Vapor penetrates surfaces and crevices- Rapid process (few hours) | - Requires costly specialized equipment- Hazardous to human health if mishandled- Not suitable for all materials | - Labs needing rapid, high-level decontamination without heat |

| Ultraviolet (UV) Light [35] | Log 3 to Log 4 | - Can be integrated for continuous operation- Low operational cost- Low residue | - Least effective method- Limited to surface disinfection- Harmful to human skin and eyes | - Supplemental control for humidity pan and surfaces; not for full decontamination [35] |

Experimental Protocols

Protocol 1: Routine Cleaning with 70% Ethanol

This protocol is for routine monthly cleaning or after any spill to maintain basic cleanliness and prevent contamination [34].

Key Materials:

- 70% Ethanol Solution: More effective than 100% at denaturing proteins throughout microbial cells [34].

- Lint-free Wipes or Non-woven Cloth: To avoid leaving fibers on surfaces.

- Neutral Detergent (Optional): For initial cleaning of heavy soiling, if recommended by the manufacturer [34].

- Sterile Distilled Water: For refilling the humidity pan.

Methodology:

- Turn off the power to the incubator and unplug it from the outlet [34].

- Remove all interior components: Carefully take out shelves, trays, fans, ducts, and the humidity pan. Place them in a clean, safe location [34].

- Pre-clean (if needed): For visible soil or spills, wipe interior surfaces with a clean cloth dampened with a mild detergent solution [34].

- Disinfect with 70% Ethanol: Spray 70% ethanol onto a wipe (do not spray directly into sensor holes). Thoroughly wipe all interior surfaces, corners, the inner door gasket, and all removed components [34].

- Reassemble: Once everything is clean and dry, replace all components in the reverse order of removal. Ensure the inner door gasket is securely and correctly in place to prevent humidity leaks [34].

- Refill Water Tray: Add sterile distilled water to the humidifying tray [34].

- Dry and Restart: Let the chamber air dry with the door ajar until no alcohol smell remains. Do not restart while damp, as this can damage gas sensors. [34] Finally, close the door and restore power.

Protocol 2: Full Heat Decontamination Cycle

This protocol describes a full decontamination cycle using an incubator's built-in moist or dry heat function to achieve a high level of sterility assurance (Log 6 reduction) [35].

Key Materials:

- The incubator's built-in decontamination program.

- Personal Protective Equipment (PPE): Heat-resistant gloves due to high chamber temperatures.

Methodology:

- Preparation: Remove all cultures and any heat-sensitive items from the chamber. The chamber should be empty.

- Initiate Cycle: Select and start the automated decontamination program (e.g., 90°C moist heat or 180°C dry heat) from the incubator's control panel [35].

- Cycle Execution: The cycle will run automatically. A typical 90°C moist heat cycle takes about 15 hours, while a 180°C dry heat cycle may take around 12 hours. These cycles include heating, holding, and cooling phases [35].

- Completion: At the end of the cycle, the chamber will be cool and dry. No further wipe-down is needed. The incubator is now ready for use [35].

Protocol 3: CO₂ Sensor Calibration

Regular calibration of the CO₂ sensor is critical for ensuring accurate gas levels, which directly control media pH [33] [31].

Key Materials:

- Independent, Calibrated CO₂ Monitor: A device like a Geotech G100, calibrated to UKAS or similar standards, to provide a reference reading [1].

- Incubator's Calibration Mode: Access to the internal calibration function, as described in the manufacturer's instructions (e.g., "3110 Incubator - TC CO₂ Calibration" guide) [33].

Methodology:

- Stabilize Conditions: Allow the incubator to stabilize at the desired temperature and humidity with the CO₂ control active.

- Take Reference Reading: Place the independent, calibrated CO₂ monitor inside the chamber and allow its reading to stabilize [1].

- Enter Calibration Mode: Access the incubator's calibration mode, often found in the service or advanced settings menu [33].

- Input Reference Value: Enter the CO₂ concentration value provided by the independent monitor as the reference point.

- Complete and Exit: Follow the on-screen prompts to complete the calibration cycle. The incubator will save the new calibration settings.

- Verify: Confirm that the incubator's displayed CO₂ value now matches the reference monitor.

Frequently Asked Questions (FAQs)

Why is 70% ethanol better than 100% for cleaning? 100% ethanol coagulates proteins on the outer cell wall too quickly, forming a barrier that protects the cell's interior. The slower action of 70% ethanol allows it to fully penetrate the microbe, ensuring complete denaturation of internal proteins and more effective killing [34].

How often should I perform a full decontamination? There is no universal rule, but a common schedule is every 3-6 months. The frequency should be risk-based: increase it if you work with prone-to-contamination cells, share the incubator with many users, or have experienced contamination issues previously [35].

My CO₂ level recovers slowly after I open the door. Is this a problem? Yes, slow recovery can lead to significant pH shifts in your culture media, stressing or damaging cells [31]. Incubators with thermal conductivity (TC) sensors are slower to recover than those with infrared (IR) sensors. If slow recovery is an issue, consider an incubator with a fast-response IR sensor [31].

Can I use DMEM in a 5% CO₂ environment? While it is conventional to use DMEM (with 44mM NaHCO₃) at 10% CO₂, many labs use it at 5%. Be aware that this will theoretically result in a medium pH of around 7.5-7.6, which is slightly above the physiological range. For low-density or slow-growing cultures, this higher pH may be suboptimal, and increasing the incubator CO₂ may be beneficial [1].

The Scientist's Toolkit

| Item | Function | Application Notes |

|---|---|---|

| 70% Ethanol Solution [34] | General surface disinfection by denaturing microbial proteins. | Primary cleaner for routine wipe-downs. Less corrosive than harsh chemicals. |

| Independent CO₂ Monitor [1] | Provides an accurate reference standard to verify and calibrate the incubator's internal CO₂ sensor. | Essential for quarterly calibration checks and troubleshooting. Should be externally calibrated annually. |

| HEPES Buffer [3] | A non-volatile buffer (pKa ~7.3) that provides additional pH stability independent of CO₂/HCO₃⁻. | Useful for procedures outside the incubator or when incubator CO₂ control is unreliable. |

| Phenol Red [3] [1] | A pH indicator dye in culture media that provides a visual cue (red/orange = good, yellow = acidic, purple = basic). | A quick, qualitative check on medium pH. Quantitative measurement requires a spectrophotometer [3]. |

| Heat-Resistant Gloves | Personal protective equipment (PPE) for handling hot components after a heat decontamination cycle. | Necessary for safety when unloading an incubator after a dry or moist heat cycle. |

In busy research laboratories, maintaining absolute stability of the incubator environment is a foundational requirement for reproducible cell culture work. Fluctuations in key parameters like temperature, CO₂, and humidity can directly compromise cell viability, alter metabolic processes, and undermine experimental integrity, potentially wasting months of valuable research [36]. Modern smart incubators, equipped with remote monitoring and alert systems, are powerful tools designed to mitigate these risks. This technical support center provides targeted guidance to help researchers, scientists, and drug development professionals troubleshoot common issues and leverage advanced features to safeguard their work, with a specific focus on maintaining the precise pH and CO₂ stability essential for reliable results.

➤ Troubleshooting Common Incubator Instability Issues

The following guides address the most frequent challenges that disrupt incubator stability.

▸ Temperature Instability

Q: My incubator temperature is fluctuating outside the acceptable range. What could be wrong?

A: Temperature instability is often caused by user interaction, calibration drift, or mechanical issues [36].

Potential Cause 1: Frequent or Prolonged Door Openings

- Issue: Every time the incubator door is opened, the internal environment is disrupted. A 30-second door opening can require over 30 minutes to fully recover to a stable 37°C [36].

- Solution:

- Organize contents and assign specific shelves to users or cell lines to minimize search time.

- Plan all necessary materials before opening the door.

- Use an incubator with an inner glass door for visual inspection without opening the main door [36].

Potential Cause 2: Incorrect Set Point or Calibration Drift

- Issue: The temperature set point may have been inadvertently changed, or the sensor may have lost accuracy over time [36].

- Solution:

- Verify the temperature set point is correctly set to 37°C.

- Perform regular sensor calibration. Annual recalibration is strongly recommended [36].

- For immediate verification, attach a calibrated secondary thermometer to the inside of the glass door to compare readings with the incubator's display [36].

Potential Cause 3: Inner Door Gasket Leakage

▸ CO₂ and pH Instability

Q: The CO₂ levels in my incubator are unstable, which is affecting the pH of my culture medium. How can I resolve this?

A: CO₂ instability directly impacts pH in bicarbonate-buffered media, as CO₂ interacts with humidity to form carbonic acid [36].

Potential Cause 1: Defective or Inaccurate CO₂ Sensor

- Issue: A malfunctioning sensor provides false readings, preventing the system from injecting the correct amount of CO₂.

- Infrared (IR) sensors are more accurate and less affected by temperature and humidity.

- Thermal Conductivity (TC) sensors are more affordable but highly sensitive to environmental fluctuations, and door openings can significantly reduce their accuracy [36].

- Solution:

- Use a portable CO₂ gas analyzer to verify the internal concentration.

- Calibrate the incubator's gas injection system as per the manufacturer's schedule.

- If problems persist, the sensor may need service or replacement.

- Issue: A malfunctioning sensor provides false readings, preventing the system from injecting the correct amount of CO₂.

Potential Cause 2: Blocked or Limited Gas Supply

- Issue: A partially opened cylinder valve, clogged regulator, or frozen regulator (from rapid gas expansion) can restrict CO₂ flow [36].

- Solution:

- Inspect the entire gas supply system, including the cylinder, connections, and hoses.

- Ensure the CO₂ cylinder valve is fully open.

- Check the gas input pressure for any blockages or low pressure.

Potential Cause 3: Frequent Door Openings

- Issue: Door openings release CO₂, forcing the system to constantly replenish it, which can lead to overshooting or undershooting the set point [36].

- Solution: Implement the same door-management strategies listed in the temperature section above.

▸ Humidity Instability

Q: The humidity in my incubator won't stabilize, leading to media evaporation or condensation. What should I check?

A: Proper humidity (often >90%) is vital to prevent medium desiccation and control condensation, which can promote contamination [36].

Potential Cause 1: Low Water Level or Poor Air Circulation

Potential Cause 2: Clogged Filters

Potential Cause 3: Ambient Laboratory Conditions

- Issue: The external lab environment (e.g., a cool, dry room) affects the incubator's ability to maintain internal humidity [36].

- Solution: While difficult to control, be aware that ambient conditions can extend recovery times after door openings.

➤ Essential Maintenance and Monitoring Protocols

Preventive maintenance is the most effective strategy for ensuring incubator stability.

▸ Preventive Maintenance Schedule

Table 1: Recommended Preventive Maintenance Activities and Frequencies

| Task | Frequency | Key Steps & Notes | Reference |

|---|---|---|---|

| Check & Refill Water Pan | Weekly | Use sterile distilled water only. Prevents desiccation and contamination. | [6] |

| Inspect Air Inlet Filters | Weekly/Bi-weekly | Check for clogs. Change based on lab traffic and air quality. | [6] |

| Exterior Cleaning | Weekly to Monthly | Use mild detergent or bleach solution. Frequency depends on lab traffic. | [6] |

| Interior Cleaning | 1-2 times per month | Use 70% ethanol or isopropyl alcohol. Pay special attention to seams and the door gasket. | [6] |

| Change Gas Supply Line Filter | Every 5th gas tank or when discolored | Ensures clean gas delivery. | [6] |

| Temperature Sensor Calibration | Annually (minimum) | Essential for accurate readings. Verify with a secondary thermometer. | [36] |

| Full Decontamination Cycle | As per lab SOP (e.g., quarterly) | Use 145°C dry heat or H₂O₂ vapor cycle if available. Not a replacement for cleaning. | [6] |

▸ Experimental Protocol: Temperature Mapping and Sensor Verification

Temperature mapping validates that the entire incubator chamber provides a uniform, stable environment, identifying potential hot or cold spots [36].

- Stabilization: Allow the incubator to stabilize at the desired set point (e.g., 37°C). This may take several hours.

- Sensor Placement: Place calibrated, independent temperature sensors (data loggers) at multiple locations within the chamber: on each shelf, in all four corners, and in the center.

- Data Collection: Seal the incubator and start recording temperature data from all sensors simultaneously. Log data every 15 minutes.

- Duration: Continue data collection for a minimum of 24 to 48 hours to capture any fluctuations over time.

- Analysis: Analyze the collected data to identify spatial and temporal variations. All recorded temperatures should fall within the acceptable tolerance range for your experiments (e.g., 37°C ± 0.2°C).

- Action: Investigate and address any significant deviations or patterns that indicate instability.

➤ Leveraging Smart Features for Proactive Management

Modern smart incubators offer features that transform maintenance from reactive to proactive.

- Remote Monitoring and Alerts: Use smartphone apps or cloud platforms to receive real-time alerts for parameter deviations (e.g., low CO₂, high temperature) without being physically present in the lab [37] [38]. This allows for immediate intervention.

- Data Logging and Archiving: Advanced data logging features create an audit trail of all environmental parameters. This is crucial for troubleshooting past events, validating experimental conditions, and complying with regulatory standards [39].

- Automated Decontamination Cycles: Utilize built-in decontamination systems, such as H₂O₂ vaporization or 145°C dry heat cycles, to thoroughly sterilize the chamber and minimize contamination risks between experiments [6].

➤ The Scientist's Toolkit: Essential Research Reagents and Materials

Table 2: Key Materials for Incubator Maintenance and Monitoring

| Item | Function | Application Notes |

|---|---|---|

| Sterile Distilled Water | Humidification source for the incubator chamber. | Prevents mineral buildup and contamination; must be used for refilling the water pan [6]. |